engineered for chemical Spills and more

Premier Quartz

Applications For Those Who Demand The Best

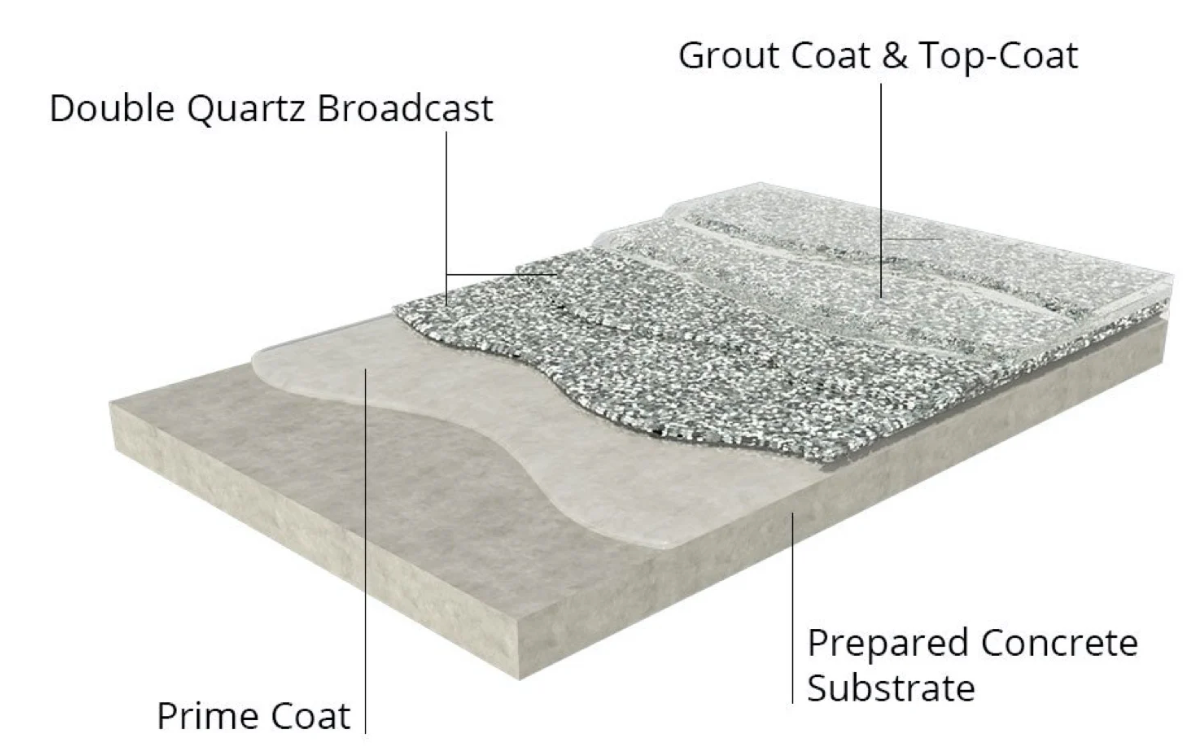

Our quartz flooring is renowned for its exceptional durability, achieved through an advanced engineering. This cutting-edge concrete coating system consists of six individual layers for optimal strength.

The quartz application ensures longevity, making it ideal for high-traffic surfaces in commercial and industrial settings.

Committed To Protecting Your Commercial and Industrial Spaces

Quartz Applications That

Will Last Decades

1. Moisture Inspection

We start every floor project by inspecting the floor for moisture issues. This will determine the right product to use.

2. Concrete Grinding

Our floor preparation process begins by grinding the concrete surface to eliminate any remnants of previous paint, adhesive, stains, dirt, and oils. This action not only clears the concrete pores but also enhances the bonding of the coating.

3. Repair and Prime

We fix any chips, holes, and cracks and apply a primer. This guarantees the structural soundness of both the surface and the professional coating. Finally, we'll sand the floor once more to prepare it for the design and application.

4. Design and Application

Initially, we apply a base coat, followed by a quartz broadcast onto the base coat, then we apply a second coat, and finally, a second quartz broadcast.

5. Seal and Protect

Once the floor is prepared, we will apply a protective top coat that is UV stable, light reflective, and offers excellent protection against damage, stains, and normal wear and tear.

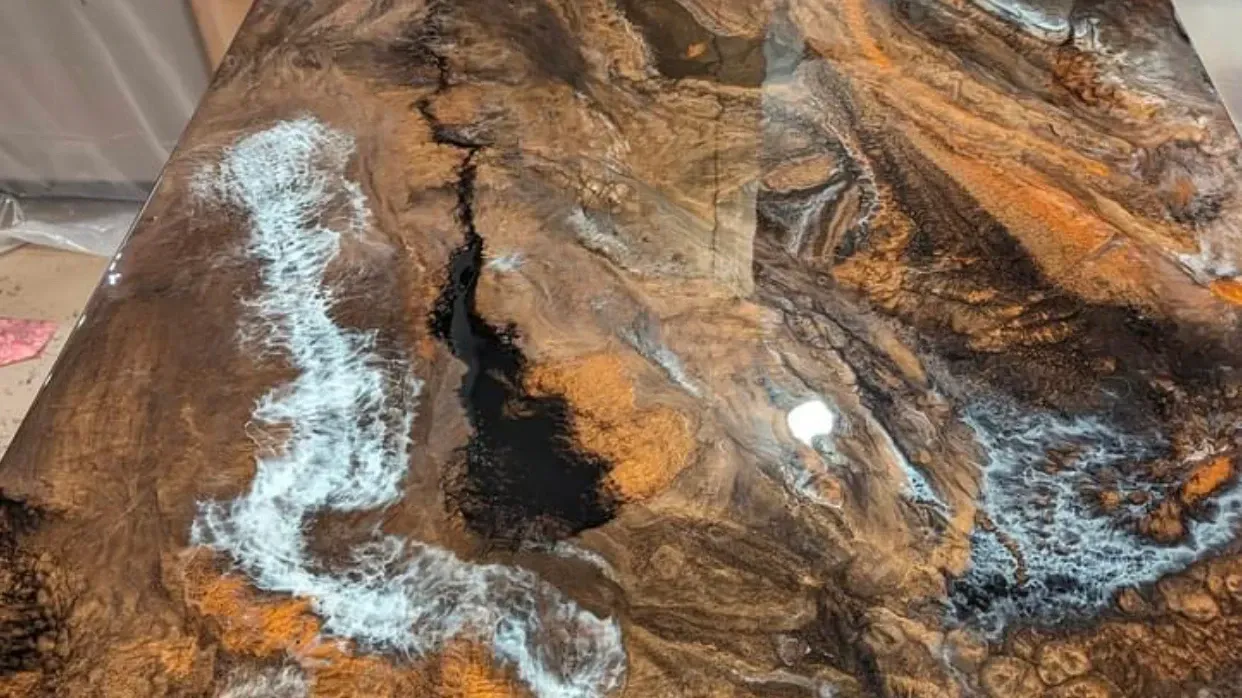

Personalize Your Quartz

We are dedicated to personalizing your space. Explore our quarts color blends and customizations.