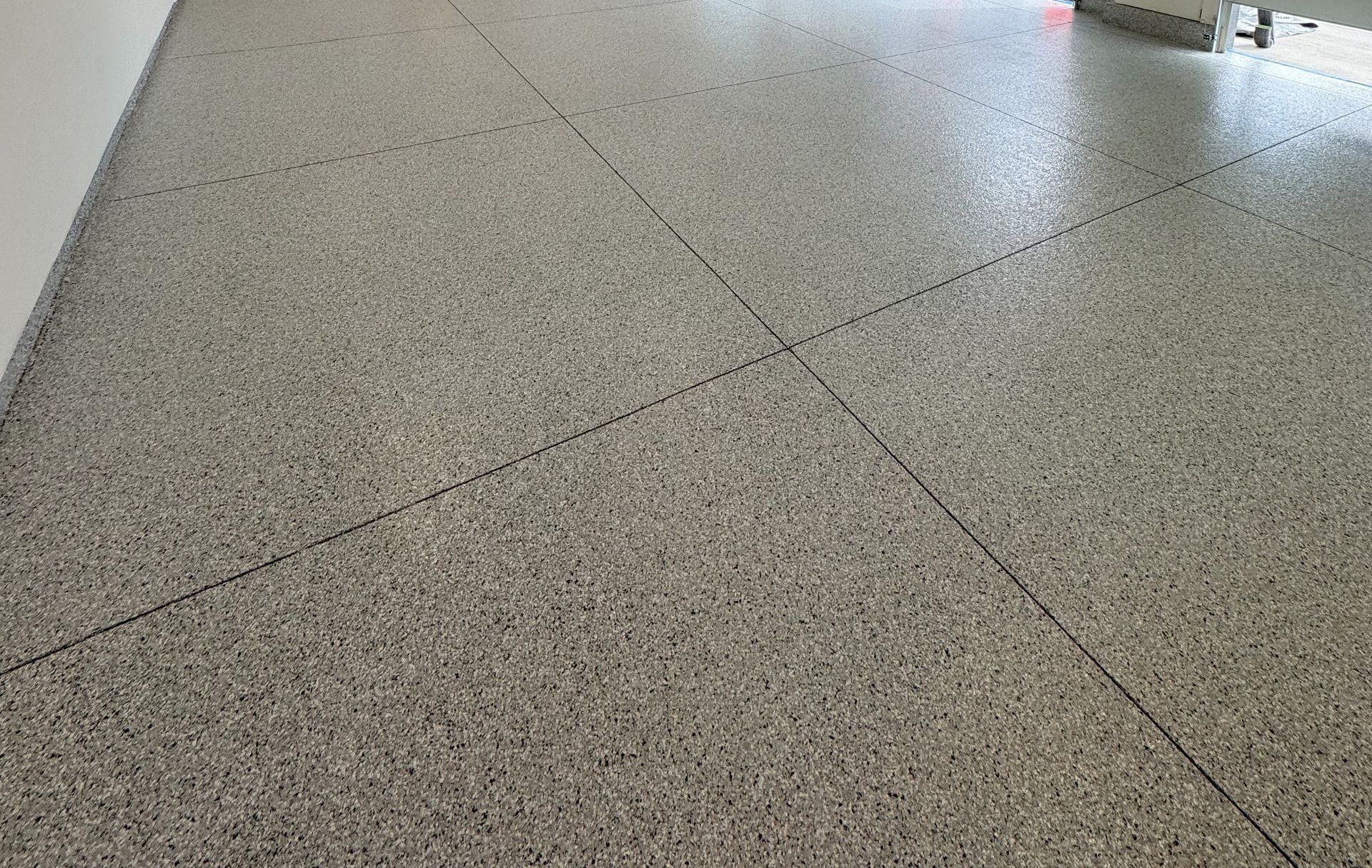

Premier Flake

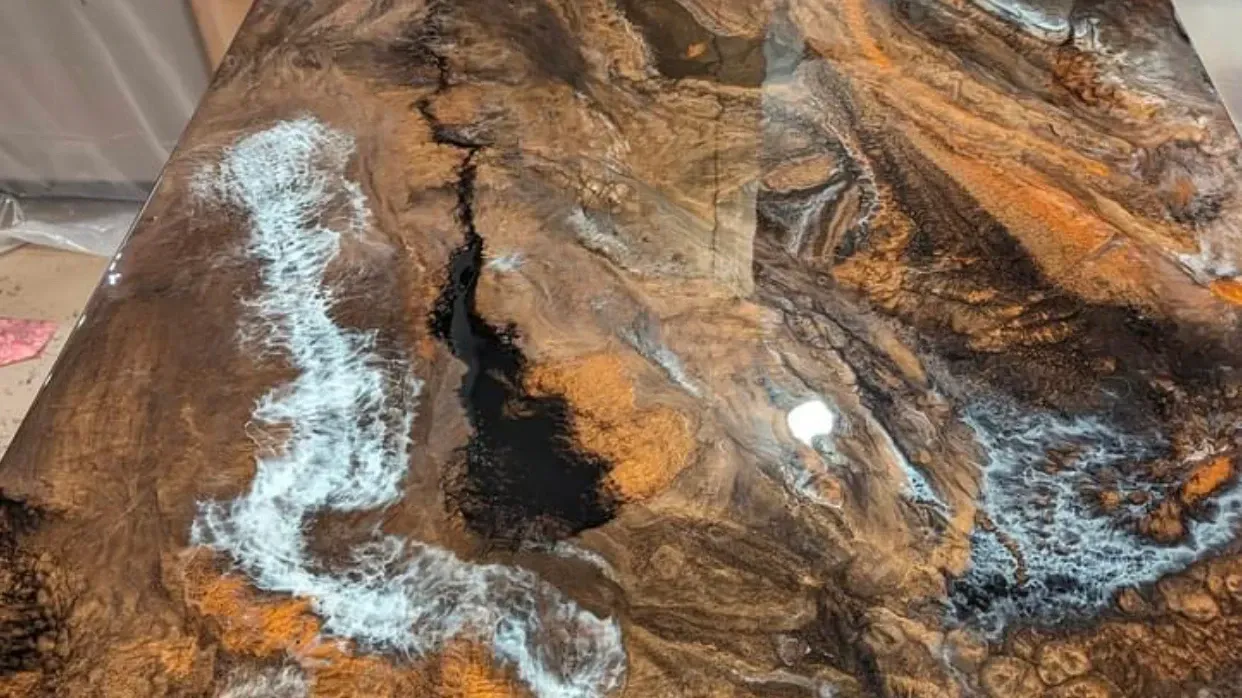

Applications For Those Who Demand The Best

Why Apex’s 2-Day System Outlasts a One-Day Floor

At Apex Custom Coatings, we don’t rush the process — we build floors to last 15–20+ years, not just look good for a few seasons. Many “one-day” systems skip crucial steps to save time, but that often comes at the cost of long-term durability.

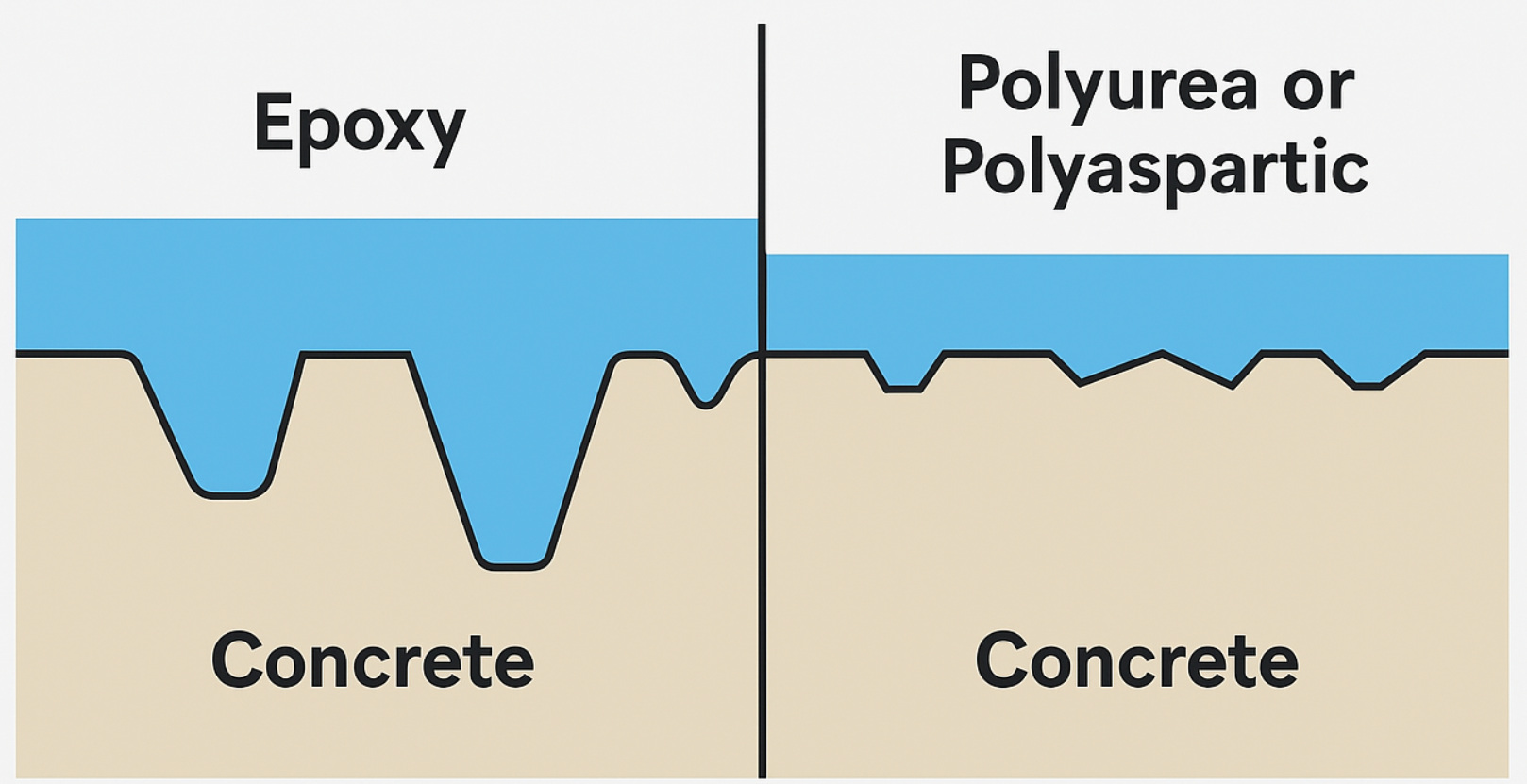

Our 2-day system uses 100% solids industrial-grade epoxy as the basecoat — not watered-down or fast-cure blends. This allows for:

- Deeper penetration into the concrete, forming a stronger mechanical bond

- Thicker, more even coverage

- No shrinkage or premature failures from accelerated cure times

Paired with a polyaspartic topcoat, our floors are built to stand up to hot tires, UV, moisture, salt, and heavy wear.

Step 1: Free On-Site Bid & Consultation

We meet with you at the project location, assess the condition of the concrete, discuss your goals, and walk you through color and finish options. You’ll get a clear quote with no surprises and expert recommendations based on your space.

Step 2: Surface Prep (Day 1)

- We start with diamond grinding using industrial equipment to open the pores of the concrete and remove any old coatings, stains, or contaminants.

- All cracks are filled using commercial-grade repair compounds.

- This prep ensures the epoxy bonds deep into the concrete instead of just sitting on the surface like cheap DIY kits or fast-cure alternatives.

Step 3: Epoxy Basecoat Application (Day 1)

- We apply a thick, self-leveling layer of 100% solids epoxy. This forms the foundation of the system.

- Flake Broadcast: We apply full broadcast of decorative flakes into the wet epoxy.

We then let the epoxy cure fully overnight, which is key to achieving the bond strength and coating thickness that lasts decades — not years.

Step 4: Sanding, Scraping, and Detail Work (Day 2)

- The next day, we return to scrape and sand the surface to remove access flake and achieve the proper grit.

- We handle any touch-ups or edge detailing before applying the topcoat.

Step 5: Polyaspartic Topcoat Application (Day 2)

- We apply a high-performance polyaspartic topcoat that adds:

- UV resistance (won’t yellow in sunlight)

- Chemical resistance

- Scratch and impact protection

- Slip resistance (optional grip additive)

This coat seals the floor tight, making it easy to clean and ready for decades of performance.

Step 6: Final Walkthrough & Care Instructions

- Once installed, we walk the job to ensure satisfaction, detailing potentially overlooked spots.

- You'll get simple instructions for cleaning and long-term care, so the floor stays looking great for years.

- Walkable in 24-Hours!

🔧 Summary:

✔️ Built to last 15–20+ years

✔️ Industrial 100% solids epoxy = deeper bond

✔️ Polyaspartic topcoat = next-level durability

✔️ Never rushed — always owner-installed quality